There are few companies, in any industry, with the type of prestige that McLaren F1 has. McLaren is the second most successful Formula One team in history, having competed and succeeded in a sport unquestionably acknowledged as the pinnacle of motorsports.

When a company like McLaren, with all of the resources and financial wherewithal of a major player in the most expensive sport in the world, announces that they will utilize 3D printing technology, many observers immediately take notice.

Once upon a time, 3D printing technology was used as a niche tool for ultra-wealthy car collectors, like Jay Leno. That video, made in 2009, references how Leno would utilize 3D printing to re-create exclusive or rare car partsthat were too uncommon to reliably find.

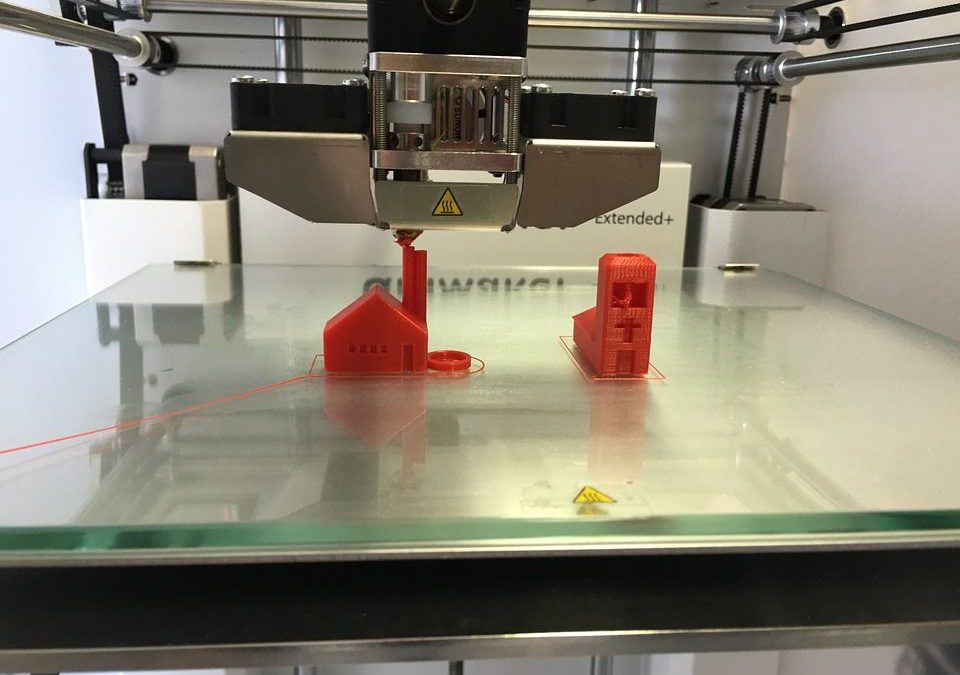

This kind of utility demonstrates the immense potential of 3D printing. There will be an inflection point for 3D printers as a common tool that almost every household has, but it hasn’t happened… yet. 3D printers are increasingly common, but not common enough (yet!) to become a mainstream mechanism. It is not hard to see that time coming up right around the corner, however.

For bigger car companies that can afford the still niche 3D printing technology, however, these printers are gaining a larger and larger share of their manufacturing capabilities. Privateers have built whole cars out of 3D printed materials; Honda built a single-seater with ~50 miles of range exclusively out of 3D printed materials. These are exceptions, of course, but still an intriguing development.

According to MachineDesign.com, Ford has been designing roughly 15% to 20% of its car prototypes via 3D printer to reduce design lag time. Reducing design time, of course, means faster development from prototypes to manufacturing, helping car companies better capture current trends with new vehicle offerings.

Perhaps more interestingly, many car companies are utilizing 3D printing to replace older parts wherever possible. For dealership maintenance departments and mechanics, rather than relying on large stores of older parts, they can simply recreate a part they might need via 3D printing. That would reduce part-purchasing overhead, storage and space utilization; a single 3D printer could save a mechanic substantial amounts of time and money in all three categories.

The final frontier, however, might be that 3D printing utilizing metal components is only accounting for 1/90th of the total market for 3D printing, currently. As metal is integrated more and more into 3D printing, it is highly likely that more and more autoparts will be designed, built and maintained with 3D printing.

You can see what’s around the horizon for 3D printing: huge profits and a bigger stake in the future of the auto-industry. It may take some time, but it is a near certainty that it will happen.